High Capacity Multilayer Collectors HC_2M200

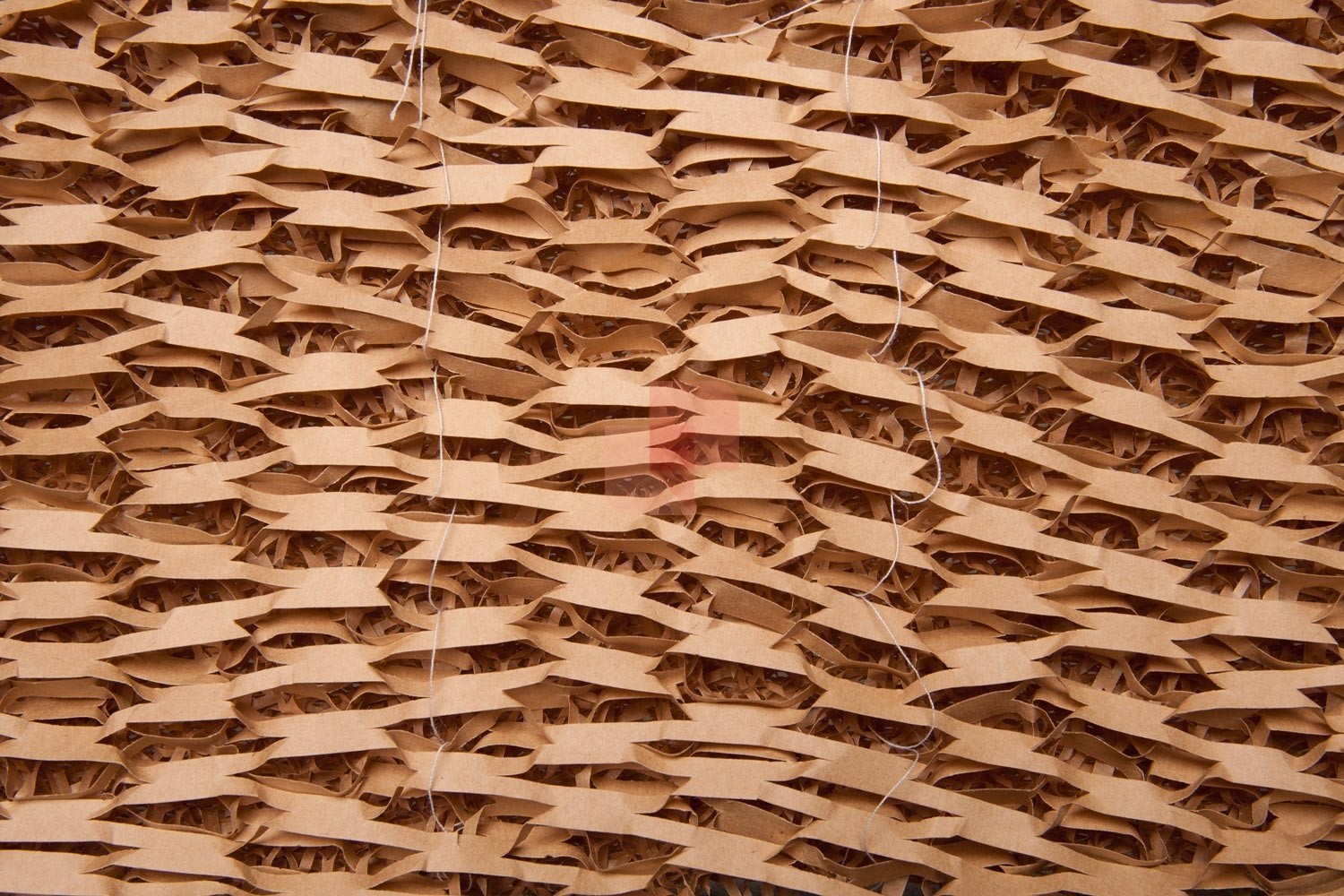

The Columbus® High Capacity 2M200Multilayer Collector is comprised of layers of slit and expanded kraft media, with a final mini-mesh layer with a synthetic fine fibre post-filter: 20 µm.

The High Capacity Multilayer Collectors HC_2M200 has been designed to solve difficult dry overspray problems in applications where it is required a higher efficiency than the High Capacity EuroSupra© 2 (HCS2) collector, combined with the high holding capacity of the High Capacity 2M (HC2M) collector.

Technical Features

- Code IT

- 152S752

- Code US

- Label Color

- White

- Efficiency

- 99.2 - 99.6 %

- Holding Capacity

- 9 kg/m²

- Dimensions

- 1000 × 100 cm

- Volume

- 0.20 m³

- Weight

- 6.00 kg

Applications

The 2M200 High Capacity Multilayer Collector is suitable for single layer filtration or pre-filtration, designed to solve difficult dry Overspray problems.

Areas

Layers

The 2M High Capacity Multilayer Collector consists of the following layers, in the direction of Air Flow:

- HC (High Capacity)

- HC+ (Reverse High Capacity)

- HC (High Capacity)

- L (Large Layer)

- Lx (Large Crossed Layer)

- Lx+ (Large Crossed Layer)

- S (Small Layer)

- MM (Mini-Mesh Layer)

- MM (Mini-Mesh Layer)

- MM (Mini-Mesh Layer)

Efficiency & Holding

Overspray collectors are not commodity items and all do not perform equally well on every coating. Specific types of coatings require certain collector designs and performance levels.

The four primary categories used to assess the overall effectiveness of a particular overspray collection system are as follows:

EFFICIENCY (formally known as “arrestance efficiency” or “weight arrestance”)

The average percentage of particulate extracted or collected from the exhaust air. The higher the collector efficiency, the cleaner the exhausted air and spray booth ducts, fan, neighboring properties, plant roof, etc. Higher efficiency lowers booth maintenance costs and, with less buildup, greatly reduces the chance of a duct fire.

AIRFLOW RESISTANCE

The measure of resistance encountered by the particulate-laden air as it passes through the collector. (Generally it is stated in inches of water column, the static pressure required to draw air through the filter.) As the collector begins to load, the resistance increases. The velocity of the air through the booth also influences the initial resistance figures and, therefore, the holding capacity and service life. The importance of proper airflow in overspray collection cannot be overemphasized. The uniformity of airflow and increased efficiency minimizes the amount of overspray deposited where it is not wanted – in difficult to clean areas within the booth, inside of the exhaust duct, on fan blades, plant roof, neighboring properties, parked cars, etc.

HOLDING CAPACITY

The amount (weight) of overspray a collector will hold before its resistance to airflow becomes prohibitive. A collector should be able to hold overspray throughout its entire depth, which is referred to as depth loading.

SERVICE LIFE

The length of time a collector performs effectively in terms of hours or shift periods before the resistance to airflow becomes prohibitive.

—

The performance of the product described in this page varies and is characteristic of each individual installation; it must therefore be measured on the system.

As a guideline, we provide some experimental data:

|

Coating Type

|

Efficiency

|

Holding Capacity

|

|---|---|---|

| Bake-dry Enamels | N/A - 99.6 % | N/A - 8.5 kg/m² |

| Oven cured waterborne enamels | N/A - 99.2 % | N/A - 9 kg/m² |

Product Line Applications

Rating Legend

- 5 Excellent Performance

- 4 Very good Performance

- 3 Good Performance

- 2 Moderate Performance

- 1 Not Usually Recommended

|

Coating Type

|

Rating

|

|---|---|

| Adhesives | 2 |

| Air-dry Enamels | 3 |

| Asphalts | 2 |

| Bake-dry Enamels | 4 |

| Clear Coats | 4 |

| Epoxies | 4 |

| Fiberglass | 2 |

| Frit | 3 |

| Gel Coats | 3 |

| Glazes - Fillers | 3 |

| High Solids - Enamels | 4 |

| Lacquers - Nitrocellulose | 1 |

| Primers - Air Dry | 4 |

| Sealers | 3 |

| Stains | 3 |

| Tar-like Coatings | 3 |

| Teflon | 4 |

| Urethanes | 4 |

| Vinyls | 3 |

| Waterbornes | 4 |